What is powder coating and how is it applied?

Reference

OpenAI's Answer

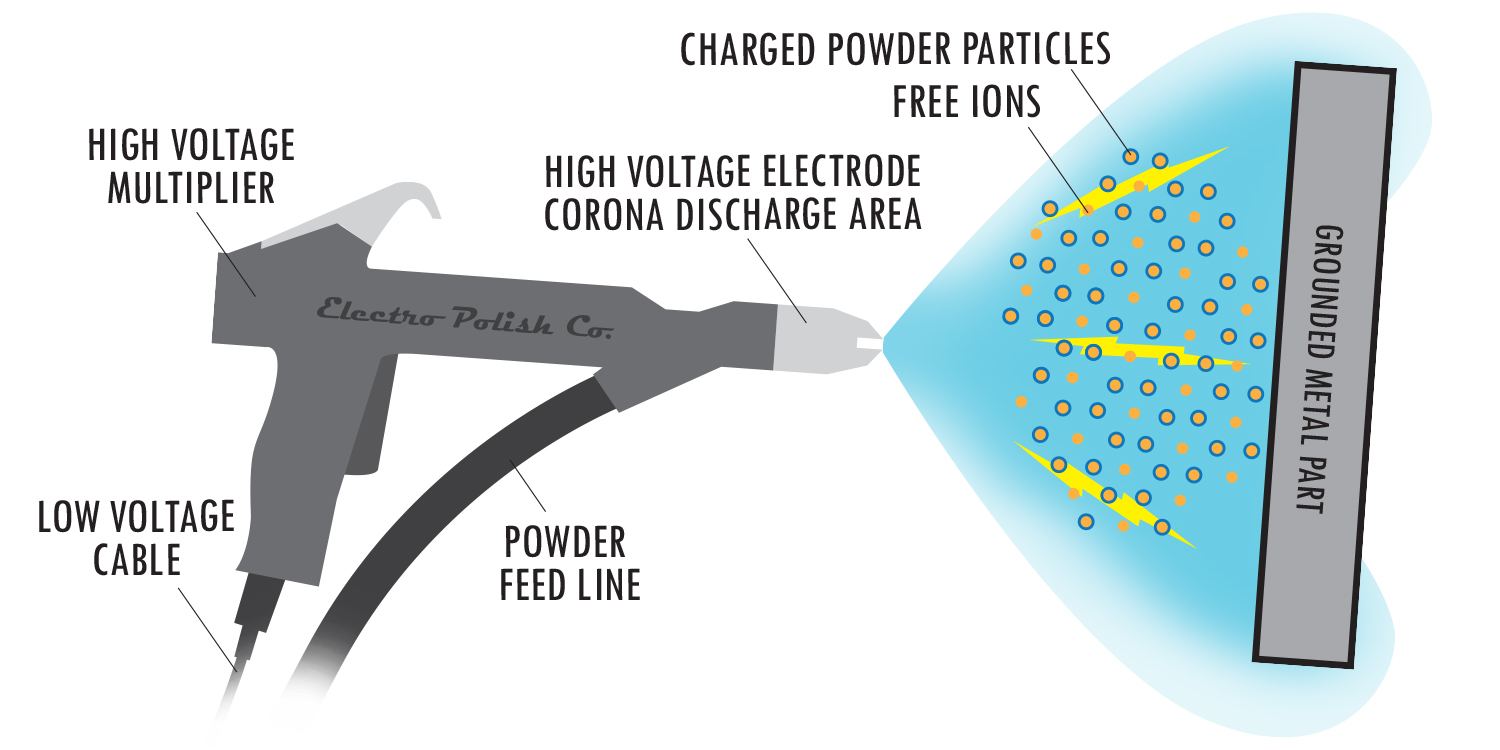

Powder coating is a type of surface finishing that involves applying a dry powder to a substrate, typically metal, which is then cured under heat to form a durable and protective layer. Unlike conventional liquid paint, powder coating is applied without a solvent, making it more environmentally friendly and efficient.

How Powder Coating is Applied:

- Preparation: The surface to be coated is cleaned and pre-treated to remove any contaminants like grease, dirt, or rust.

- Application: The powder is electrostatically charged and sprayed onto the grounded surface. This electrostatic charge helps the powder adhere evenly and reduces overspray.

- Curing: After application, the coated item is placed in an oven where the powder melts and chemically reacts to form a solid, durable finish. The curing temperature and time depend on the specific type of powder used.

Benefits of Powder Coating:

- Durability: Provides a tough, resilient finish that resists chipping, scratching, and fading.

- Variety: Available in numerous colors and textures, allowing for aesthetic versatility.

- Environmental Impact: Minimal waste and no solvents mean it is a more eco-friendly option compared to traditional paints.

For additional visuals related to the powder coating process, here are some images:

For a deeper understanding, you can refer to these sources:

These resources provide comprehensive information about the powder coating process, its applications, and benefits.