Reference

OpenAI's Answer

Engineered wood and natural wood differ in several ways regarding their applications, which are influenced by their respective compositions, advantages, and limitations.

Engineered Wood

-

Composition: Engineered wood is made by binding wood fibers, particles, or veneers together with adhesives. This blend creates various products like plywood, medium-density fiberboard (MDF), and laminate.

-

Applications:

- Construction: Engineered wood is commonly used in construction due to its strength and versatility. It is used for load-bearing applications like flooring and roof decking.

- Interior Design: Its stability makes it ideal for use in areas subject to humidity fluctuations, such as kitchens and bathrooms.

- Furniture: Engineered wood is often used in furniture making because of its cost-effectiveness and ability to be manufactured in large sheets without natural defects.

-

Advantages: Engineered wood offers greater resistance to warping and cracking compared to natural wood, making it suitable for environments exposed to moisture and temperature changes.

-

Limitations: It may not have the same natural aesthetic appeal as solid wood, which can be a disadvantage for some high-end furniture or interior designs where appearance is crucial.

Natural Wood

-

Composition: Natural wood, or solid wood, is cut directly from trees and used in its natural form without modification.

-

Applications:

- Furniture and Decor: Natural wood is often preferred for furniture due to its unique grain patterns and aesthetic appeal.

- Traditional Construction: It is used in structural components where load capacity is less of a concern, like beams and framing.

-

Advantages: Natural wood provides a unique texture and appearance that cannot be replicated by engineered alternatives. It is highly valued for its authenticity and warmth.

-

Limitations: Natural wood is susceptible to changes in humidity and temperature, which can lead to warping and expansion.

Overall, engineered wood is favored in scenarios demanding specific performance criteria such as dimensional stability and cost, while natural wood is often the material of choice for projects where aesthetics and traditional quality are prioritized.

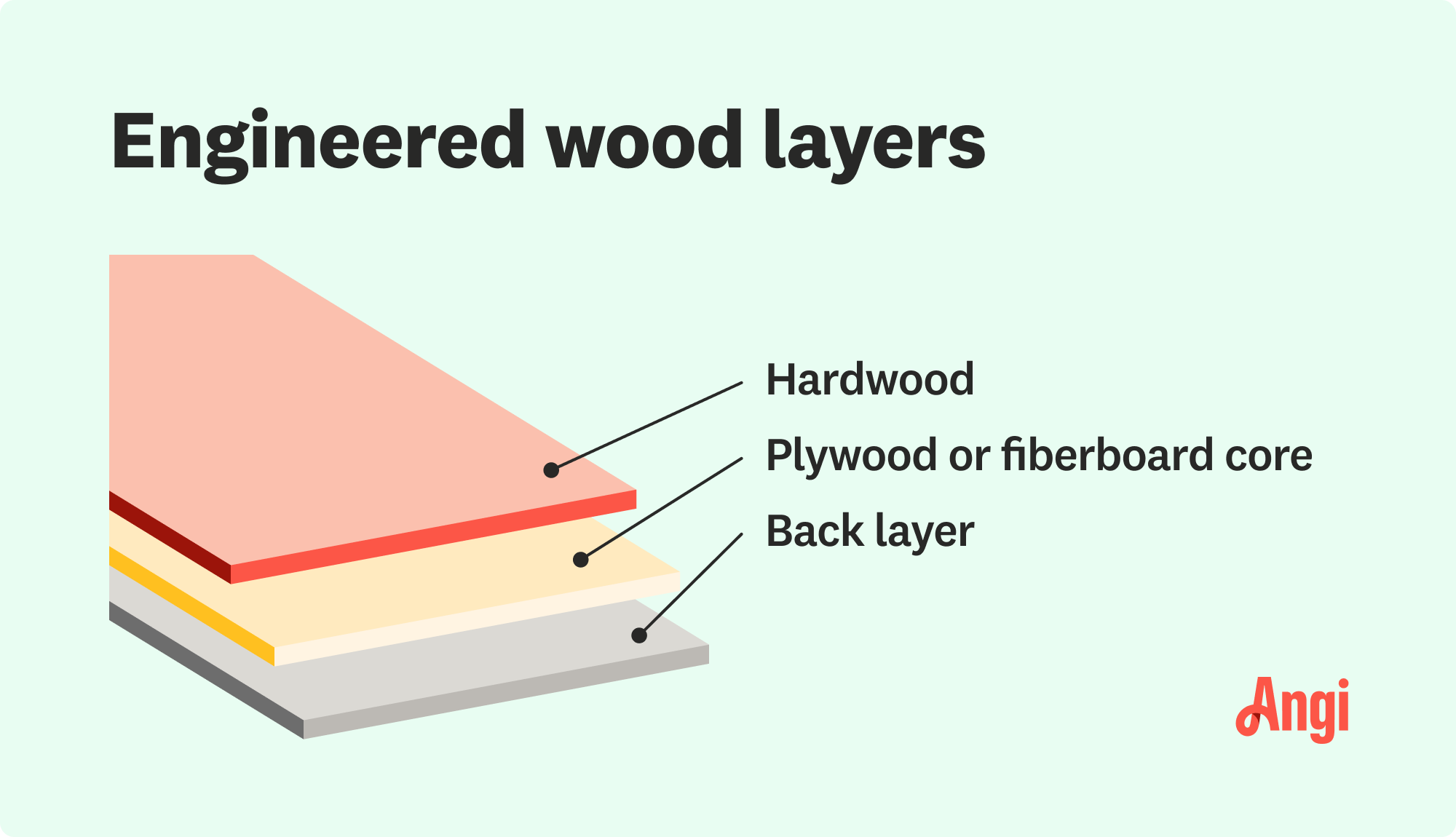

For further illustration on the structure and layering of engineered wood, you might find these images helpful:

: This image shows the layers that provide engineered wood its stability.

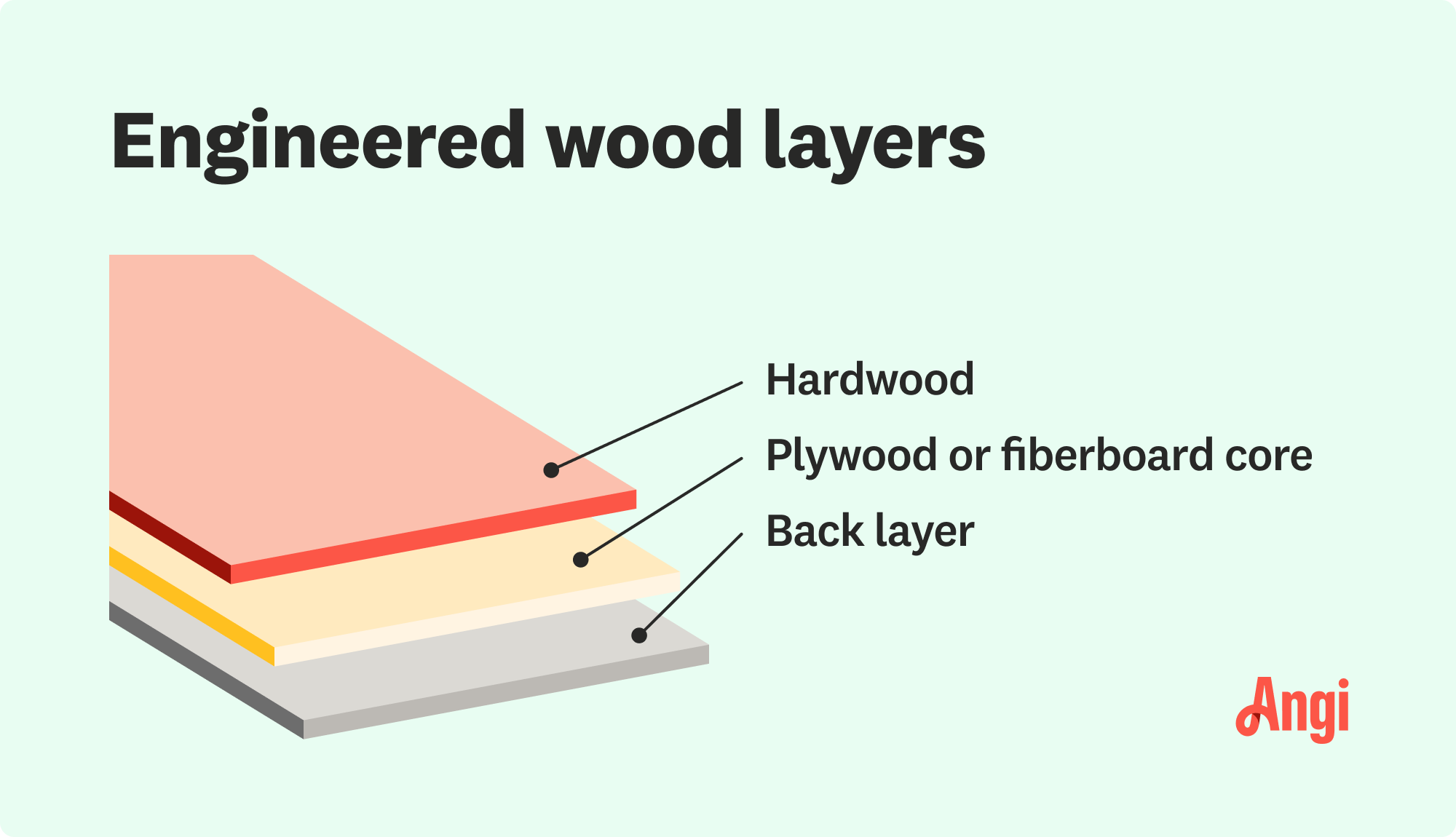

: This image shows the layers that provide engineered wood its stability. : An overview of different types of engineered wood used for various applications.

: An overview of different types of engineered wood used for various applications.

Follow Up

Related

explain about the applications of machine learning algorithms

explain about the applications of machine learning algorithms

What supporting documents are required for a B1/B2 visa interview?

larger language model

What resources are available for research on phytoremediation techniques and applications?