Reference

OpenAI's Answer

When it comes to applying paint to surfaces, various methods exist, each tailored to specific needs, surfaces, and desired finishes. Here’s a breakdown of the main techniques commonly used in painting:

1. Brushing

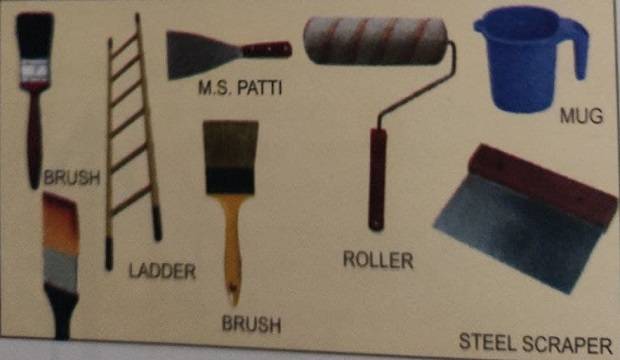

One of the oldest and most traditional methods, brushing is ideal for detailed work, edges, and areas requiring precision. The method involves using a paintbrush to apply a thin coat of paint. Brushes are highly effective for smaller or intricate surfaces like trim, corners, and tight spaces. It provides good control over paint thickness, making it suitable for touch-ups or fine finishing. However, it may leave visible brush strokes, especially on larger areas, unless the paint is applied carefully.

Applications:

- Smaller projects or areas that need precision (e.g., trim, doors, and window frames).

- Perfect for textured surfaces, as it allows for control over the amount of paint applied.

2. Rolling

Rollers are commonly used for painting large flat surfaces like walls and ceilings. Paint is applied using a cylindrical roller cover, which is dipped into paint and rolled across the surface. The technique is quicker than brushing and generally results in a more even finish with fewer brush marks. Different roller covers can be used depending on the texture of the surface being painted.

Applications:

- Ideal for walls, ceilings, and large flat areas.

- Provides an even coat and is faster than brushing, making it a popular choice for indoor and outdoor painting projects.

3. Spraying

Spray painting is a versatile and efficient method often used for both industrial and residential applications. It involves using a spray gun or airbrush to apply paint in a fine mist. This method is particularly useful for large surfaces or intricate details where a smooth, uniform finish is desired. There are several types of spray systems, including:

- Airless Spraying: High-pressure application that doesn't require air to atomize the paint, resulting in thicker coats and faster coverage.

- Air Atomized Spraying: Uses compressed air to spray paint, providing a finer finish suitable for delicate and detailed work.

- Electrostatic Spraying: Used primarily in industrial settings, it involves an electric charge to attract paint particles to a surface, resulting in minimal waste and a smooth finish.

Applications:

- Large-scale projects like furniture, fences, and automotive parts.

- Surfaces that require a flawless, uniform finish without visible brush or roller marks.

4. Dipping

In industrial applications, dipping involves submerging an object (often metal or plastic) into a large tank of paint. This technique ensures uniform coverage and is highly efficient for mass production of items like car parts, industrial machinery, or hardware. It's also used for powder coating in metal industries.

Applications:

- Industrial or mass production of small to medium-sized objects.

- Items that need a thick and durable coating, such as tools and metal components.

5. Flow Coating

Flow coating is often used for coating large flat surfaces or parts that can't be easily sprayed. Paint is applied in a controlled stream, often while the item is rotated or moved along a conveyor system. This method ensures even coverage and can be used for a variety of industrial and decorative applications.

Applications:

- Coating large, flat, and complex surfaces that are difficult to spray or brush.

- Used in high-volume manufacturing environments, such as coating metal or plastic parts.

6. Sponging and Rag Rolling

These decorative techniques involve using a sponge or a rag to apply a glaze or multiple layers of paint. These methods create texture and depth on the surface, often used in artistic applications for walls, furniture, and interior decor. The sponging technique leaves a pattern, while rag rolling gives a smoother but still textured finish.

Applications:

- Decorative painting for textured wall finishes.

- Used in artistic and custom interior designs.

7. Powder Coating

A highly durable method, powder coating involves applying a dry powder to a surface that is then cured under heat to form a tough, resilient finish. This method is mainly used for metal surfaces and is common in industrial applications like automotive parts, outdoor furniture, and appliances.

Applications:

- Ideal for metal items, especially those exposed to harsh environments.

- Used extensively for outdoor furniture, automotive parts, and appliances where durability is essential.

8. Taping and Stenciling

For projects requiring precise, clean edges or specific patterns, tape and stencils are often used. Painter’s tape is applied to areas that should not be painted, while stencils create patterns or logos. This method is frequently used for detailed wall designs, signs, and decorative finishes.

Applications:

- Perfect for creating clean lines or patterns on walls or furniture.

- Often used in DIY home improvement projects or for artistic details.

Each method has its unique advantages and is suited to different types of projects. The choice of method depends on factors like the size of the project, the type of surface being painted, and the desired finish. When choosing a method, it’s essential to consider the desired speed, efficiency, and finish quality.